A-A-55439A

3. SALIENT CHARACTERISTICS.

3.1 Interface and physical dimensions. Batteries supplied to this CID shall be as specified herein and

shall meet the requirements of SAE J537.

3.2 Containers. Containers shall be free of leaks, cracks, or other defects that would adversely affect

performance. Containers shall be of one piece construction and shall be made of non-absorbent acid-

resistant, hard rubber or polypropelene plastic.

3.2.1 Electrical breakdown. At a temperature of 80ºF (26.6 ºC) the container walls and partitions shall be

capable of withstanding for 5 seconds a voltage of 100V/mil of wall thickness for hard rubber containers,

300V/mil of wall thickness for plastic containers, (30,000 volts maximum for either hard rubber or plastic)

without being perforated or burned through.

3.2.2 Acid resistance. Specimens of the container material shall be capable of being immersed in

sulfuric acid at 150 ºF (65.5 ºC) for a period of 28 days without increasing in weight by more than 1.5

percent, increasing dimensionally by more than 2 percent, or blistering, cracking, or showing other visible

damage.

3.2.3 Impact resistance, hard rubber containers. At a temperature of 80ºF (26.6 ºC) the container shall

be capable of withstanding, without damage, the impacts from a 2 pound (.907 Kilogram (kg)) steel ball

dropped on the spans of the container positioned horizontally, with the minimum impact resistance

specified in table II. The points of impact and number of impacts shall be as specified in the BCI Battery

3.2.4 Impact resistance, plastic containers. At a temperature of 80ºF (26.6 ºC) the plastic containers

shall be capable of withstanding, without damage, the impact resistance tests entitled "Plastic Container

and Cover Testing Procedures" in the BCI Battery Technical Manual, with the minimum impact resistance

specified in table II.

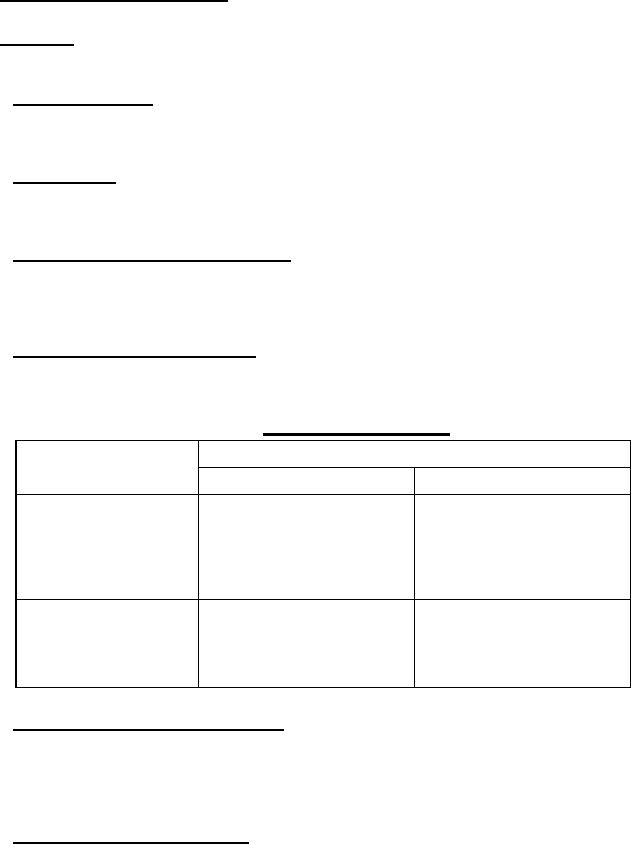

TABLE II. Container impact resistance.

Minimum impact resistance

Battery class

Hard rubber container

Plastic container

Classes 1, 3, 5, 6, and 7

12 inch/pound (1.36 newton

50 inch/pound (5.65 N m)

meters (N m)) average for all

average for all spans.

spans.

No single impact failure below

No impact failure below 8

35 inch/pounds (3.95 N m).

inch/pound (0.90 N m).

Classes 2 and 4

20 inch/pound (2.26 N m)

75 inch/pounds (8.47 N m)

average all spans.

average for all spans.

No impact failure below16

No single impact failure below

inch/pounds (1.81 N m).

50 inch/pounds (5.65 N m).

3.2.5 Bulge resistance, hard rubber containers. The hard rubber containers shall be capable of

maintaining bulge resistance when filled with water to within .625 inch (15.88 mm) from the top, having

the water heated to 158 ºF (70º C) and held at that temperature for 3 hours, and letting the water

gradually return to 75º F (23.8º C) over a period of 10 hours minimum. Maintaining bulge resistance will

be evidenced by the container not increasing in any dimension by more than .063 inch (1.59 mm) from

measurements taken at 75º F (23.8º C) prior to filling it with water.

3.2.6 Bulge resistance, plastic containers. The containers shall be capable of maintaining bulge

resistance when tested as specified in the "Plastic Container and Cover Testing Procedures" of the BCI

Battery Technical Manual at a test temperature of 80 ºF (26.66 ºC).

2

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business